顯示器模組

1. FUNCTIONS&FEATURES

Features

一 Dot Matrix: 320×240 Dots

一 LCD Mode: STN

一 Controller IC: RA8835 or Equivalent or No Controller 一 Driving Method: 1/240 Duty; 1/17 Bias

一 Viewing Angie: 6 O’clock direction

一 6800 or 8080 serial 8-Bit MPU Interface

一 Backlight: LED

一 Operating Temperature Range: -20 to 70°C;

一 Storage Temperature Range : -30 to 80°C;

Note: Color tone is slightly changed by temperature and driving voltage.

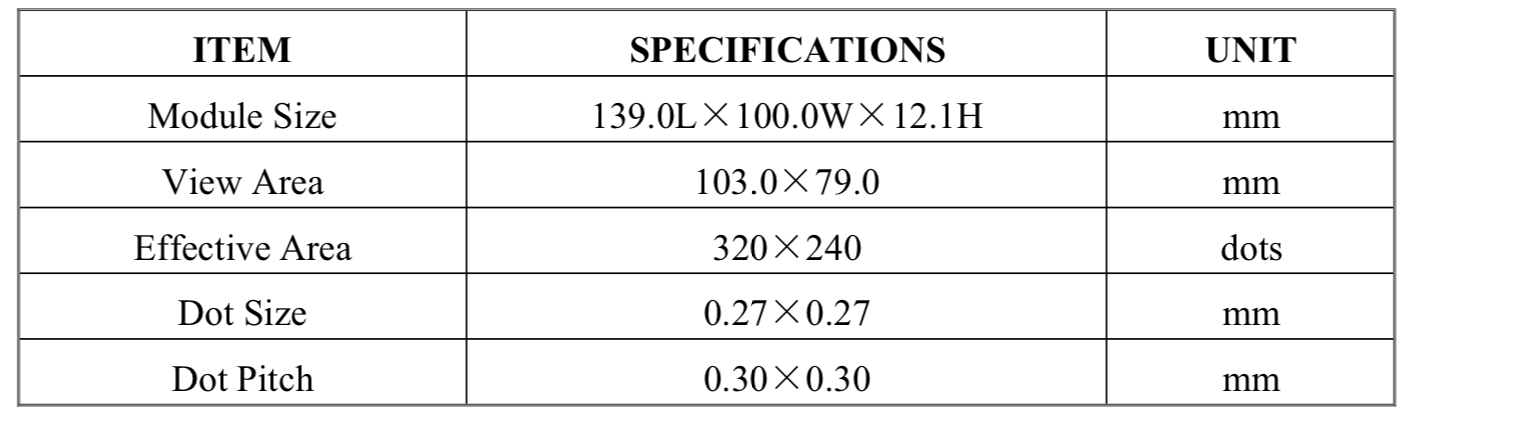

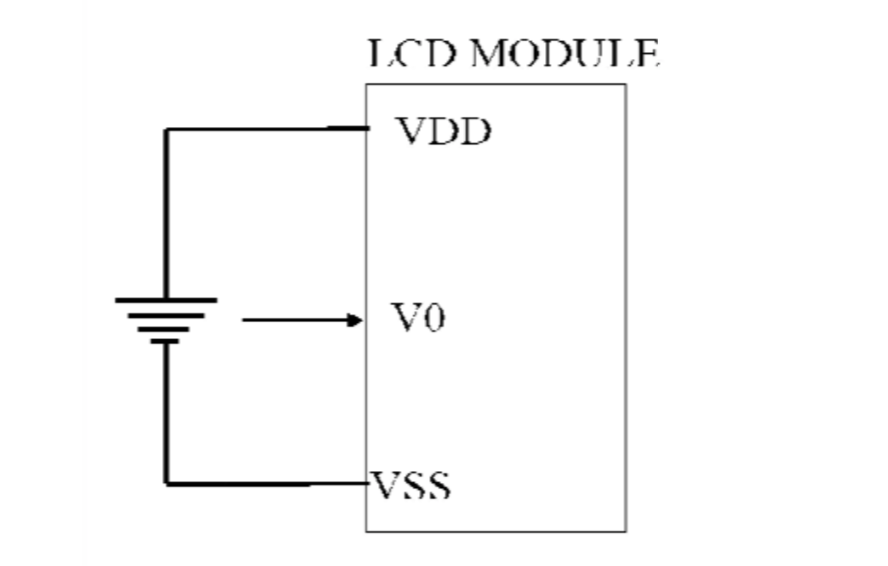

2. MECHANICALSPECIFICATIONS

3. EXTERNALDIMENSIONS

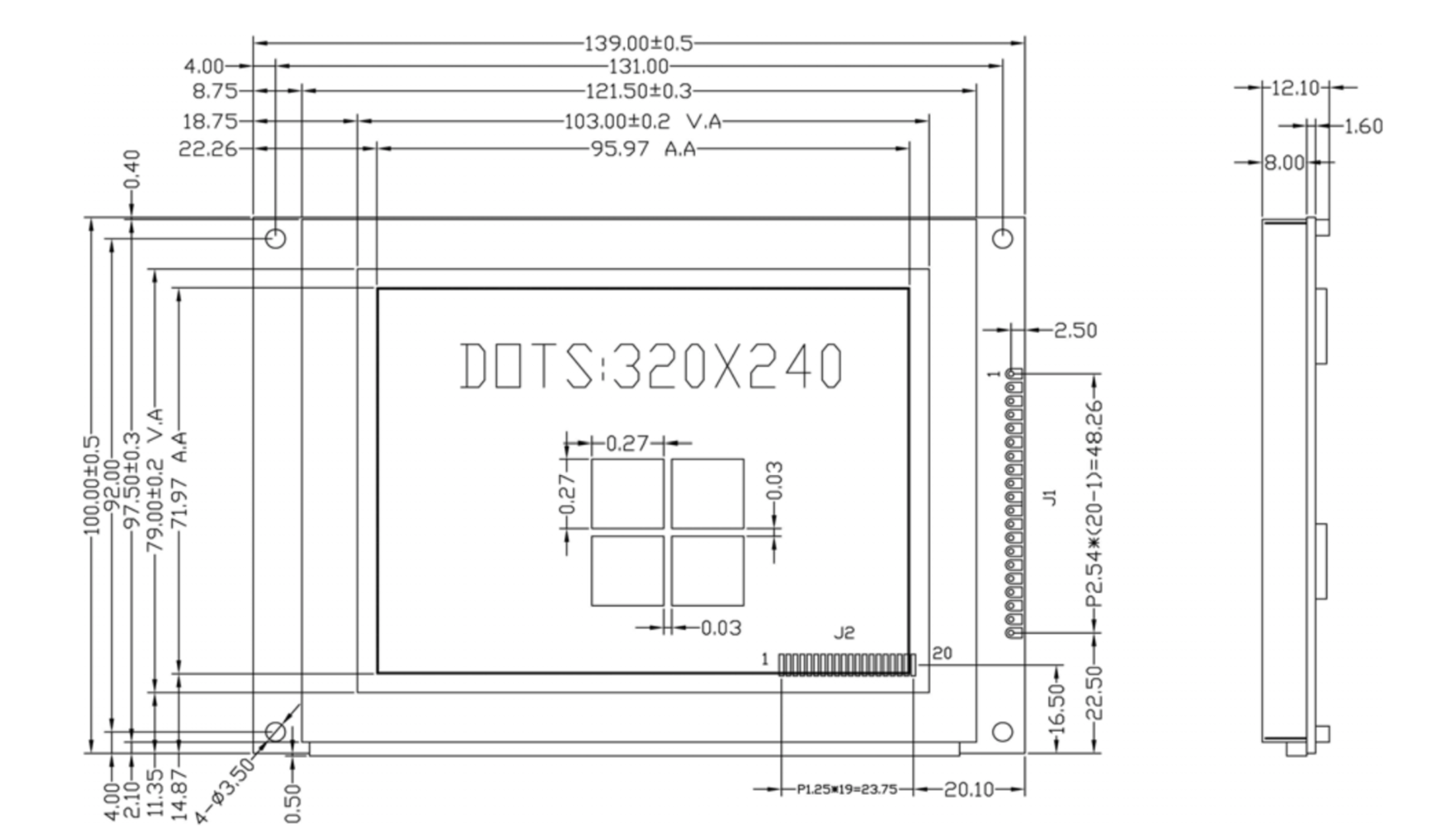

4. BLOCKDIAGRAM

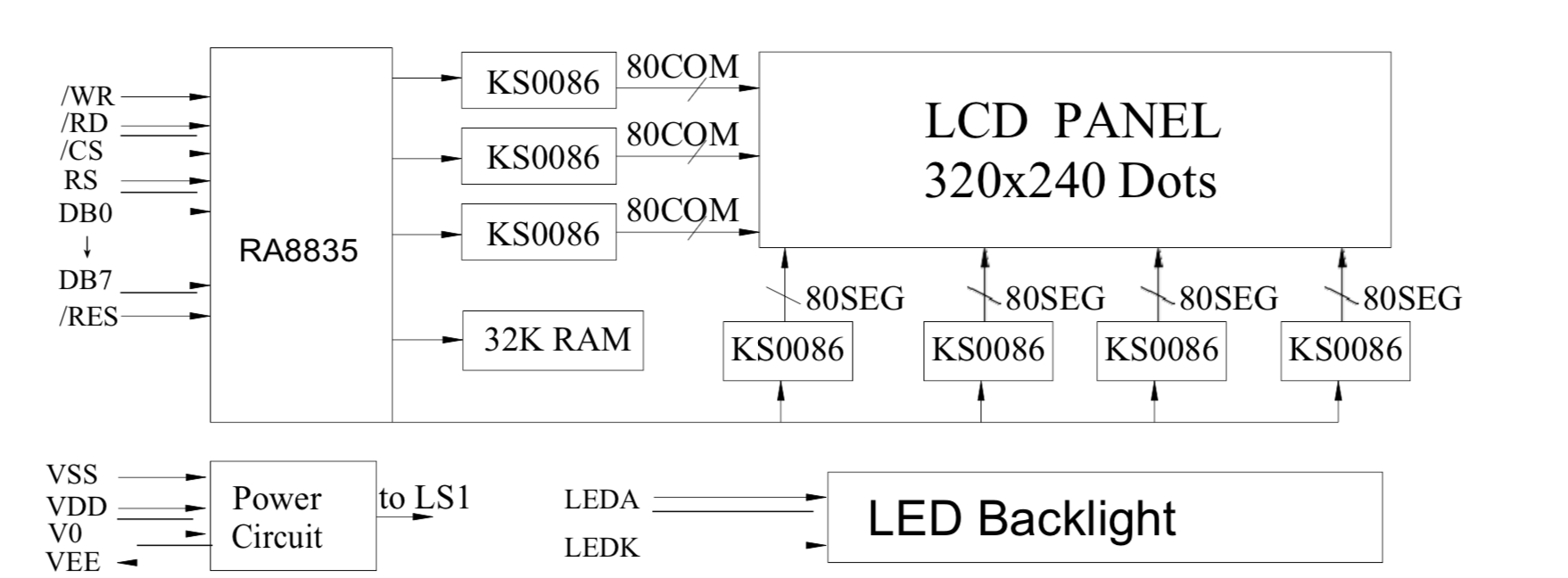

5. POWERSUPPLY

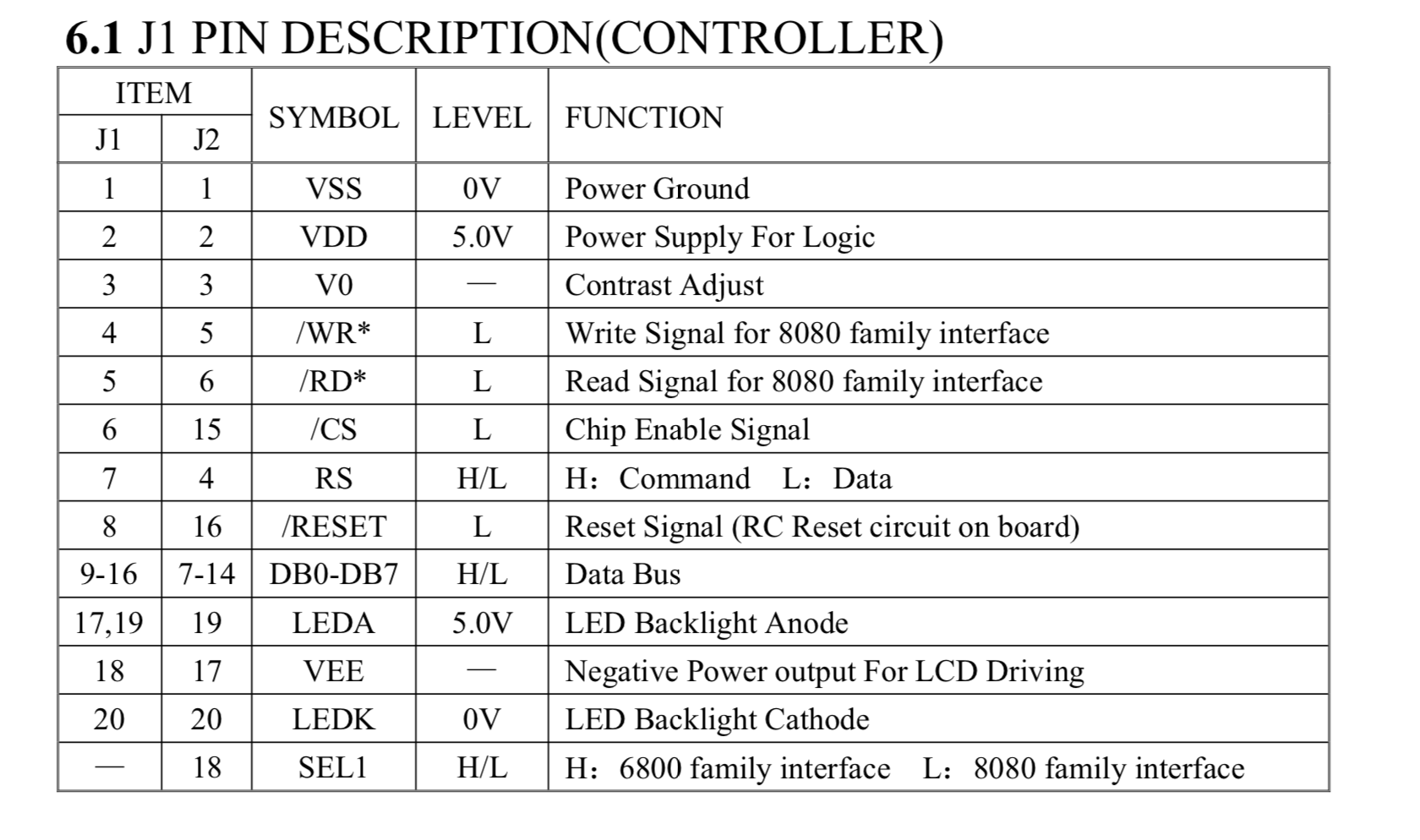

6. PINDESCRIPTION

Note:

一 When using J1 interface, 8080 family interface has been chosen default;

一 When using J2 interface, SEL1 should be used for interface choosing;

一 /WR is used as R/W for 6800 family interface, /RD is used as E signal for 6800 family

interface.

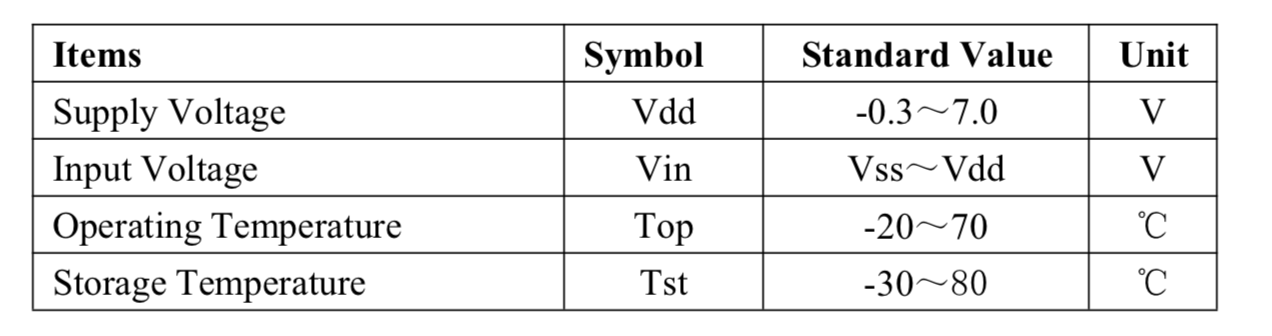

7. MAXIMUMABSOLUTELIMIT(Ta=25°C)

Note: Voltage greater than above may damage the module All voltages are specified relative to VSS=0V

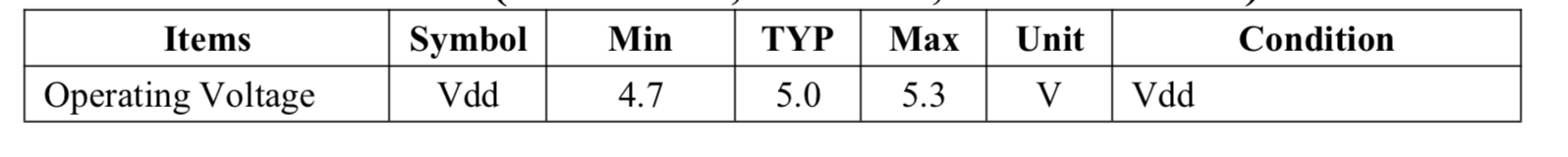

8. ELECTRICALCHARACTERISTICS

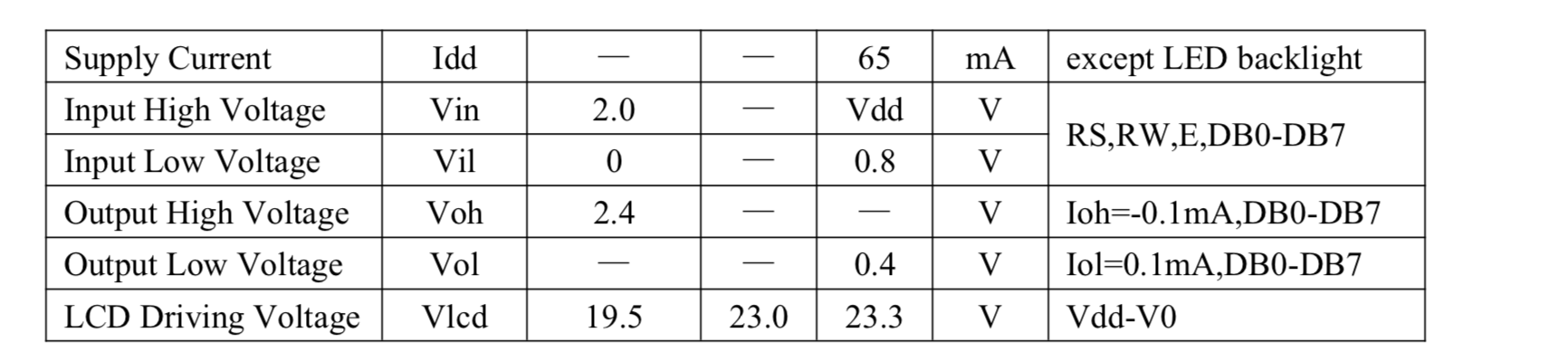

8.1 DCCharacteristics(VDD=+5V,VSS=0V,Ta=-0~+50°C)

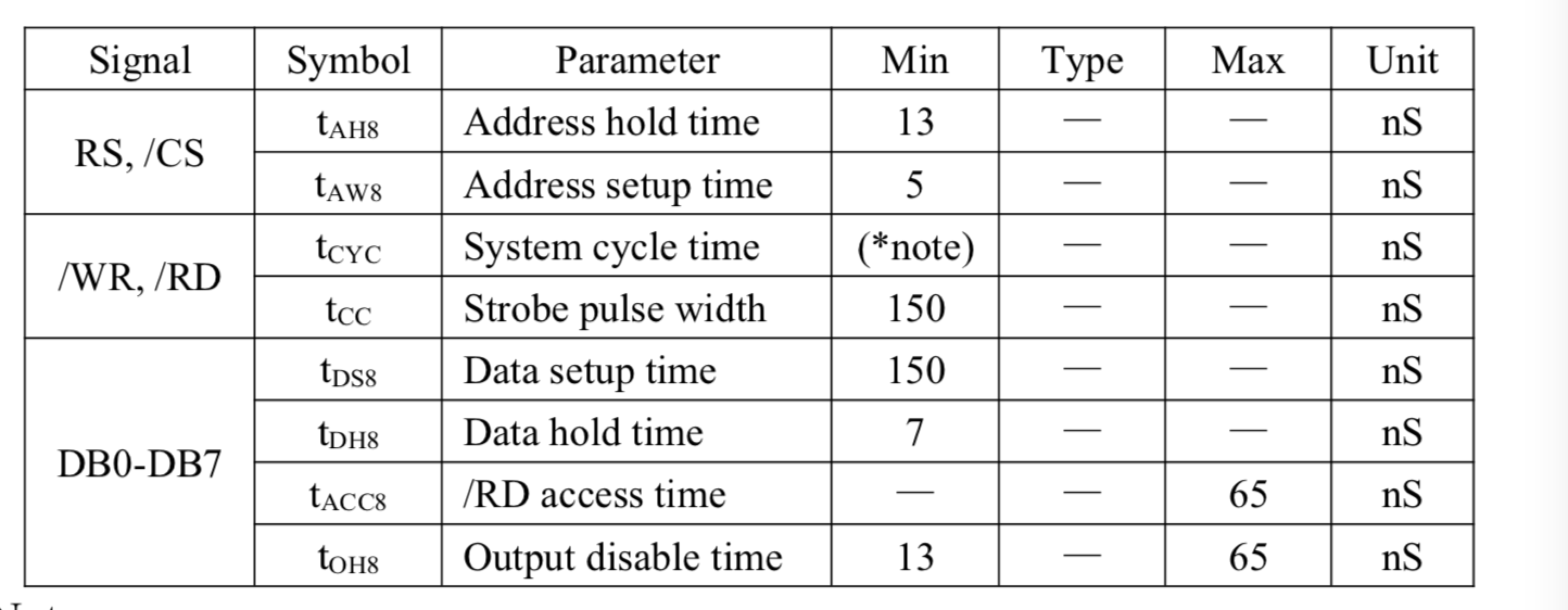

8.2AC Characteristics 8080 Family Interface(VDD=+5V, VSS=0V, Ta=-20~75°C)

Note:

一 Input signal rise/fall time should be less than 20nS; 一 For memory control and system control commands:

tCYC = 2 tC + tCC + tCEA +75 > tACV + 245 For all other commands:

tCYC = 4 tC + tCC + 30

一 Please see the RA8835 datasheet for details

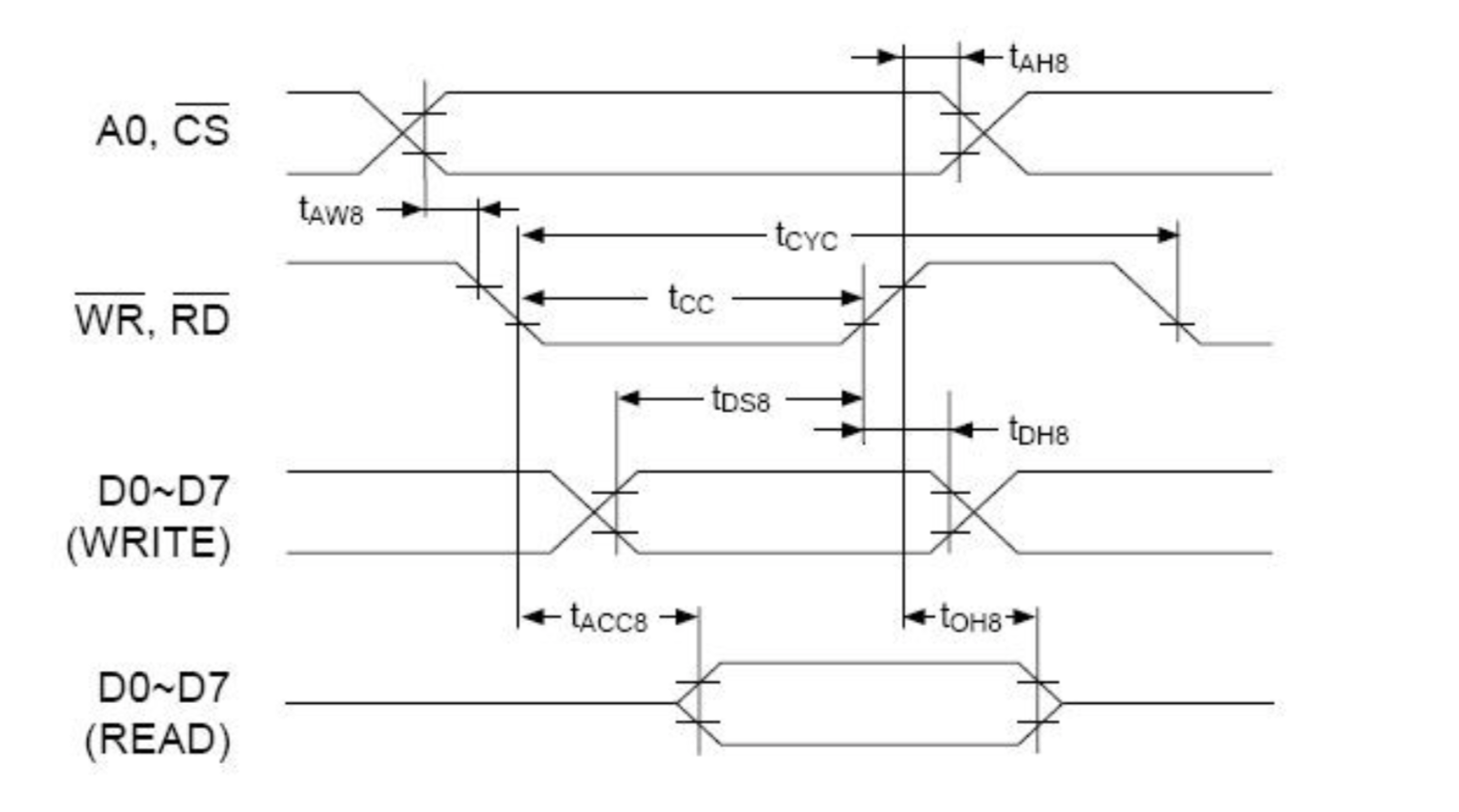

8080 family interface timing

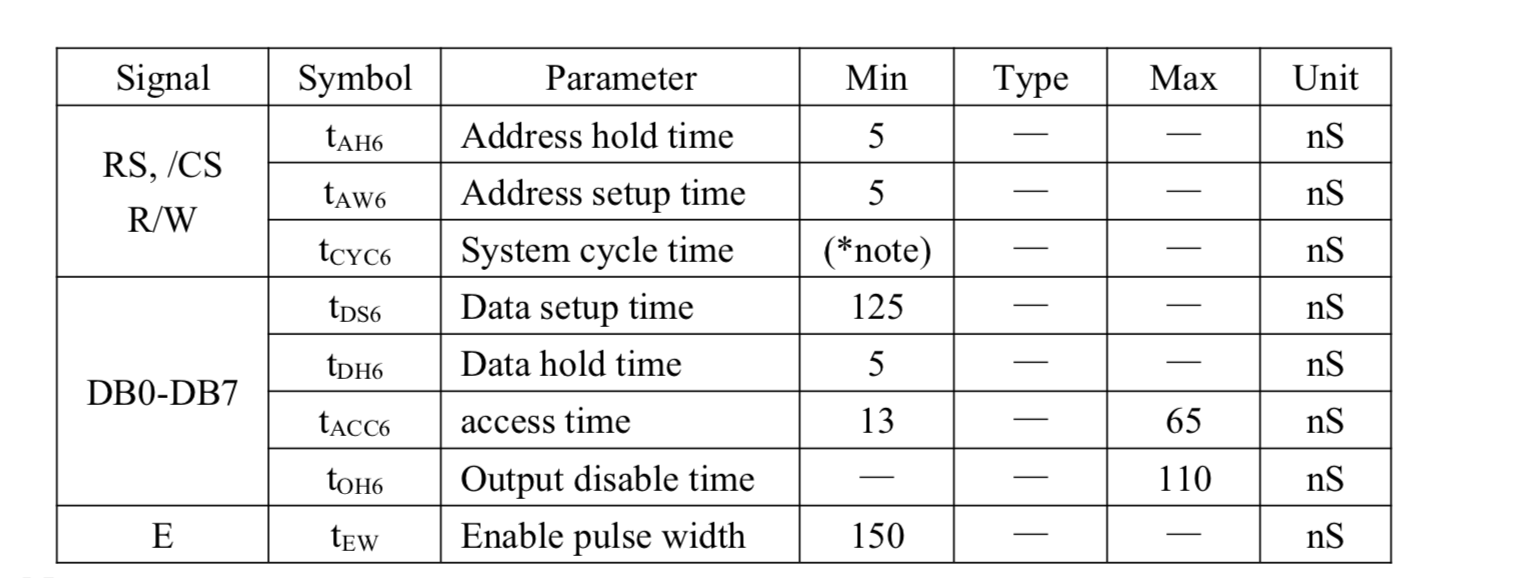

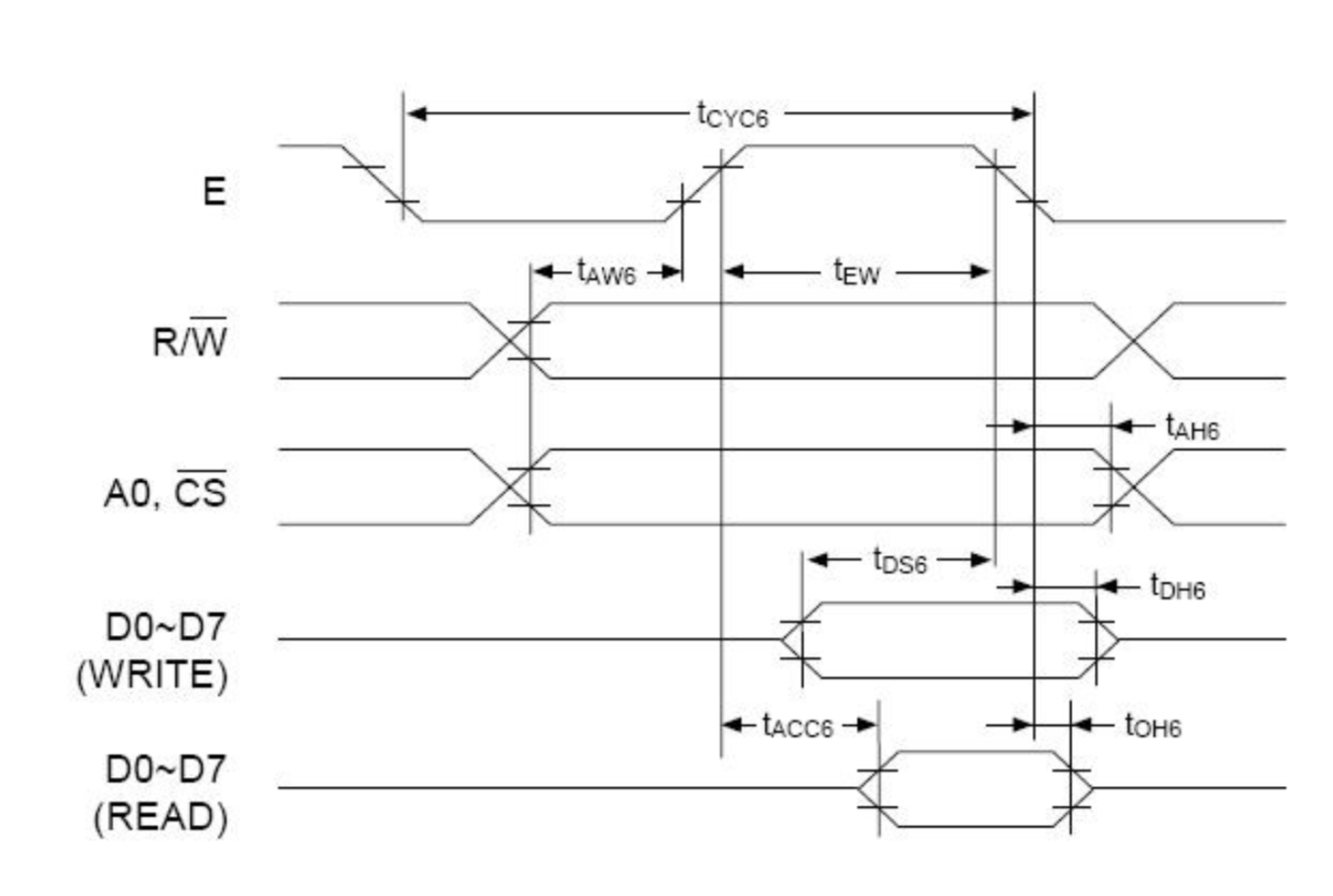

8.3 b AC Characteristics For 6800 Family Interface(VDD=+5V, VSS=0V, Ta=-20~75°C)

Note:

一 Input signal rise/fall time should be less than 20nS;

一 For memory control and system control commands: tCYC = 2 tC + tEW6 + tCEA +75 > tACV + 245

For all other commands: tCYC = 4 tC + tCC + 30

6800 family interface timing

9. FUNCTIONSPECIFICATIONS

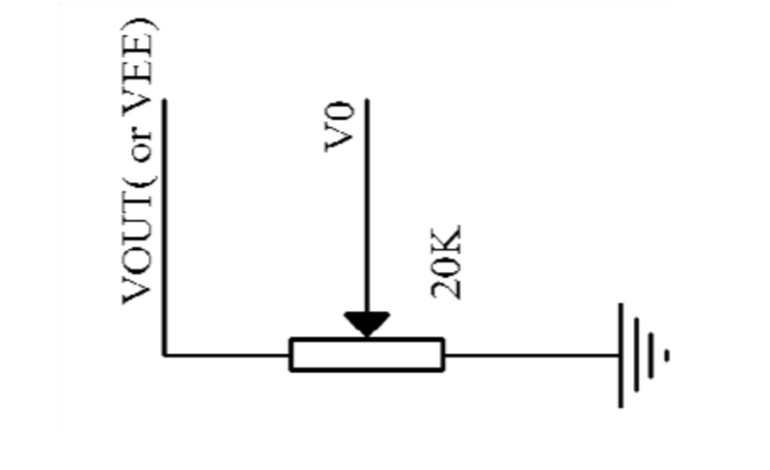

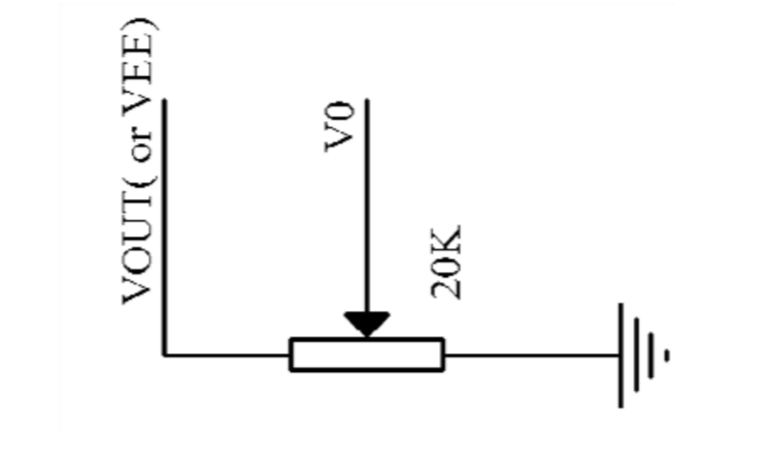

9.1. AdjustingTheLCDDisplayContrast

A Variable-Resistor must be connected to the LCD module for providing a reference to V0.The recommended value of the Variable-Resistor is 20K to 50K.

9.2. ResettingTheLCDModule

The LCD module should be initialized by setting /RST terminal at low level when turning the power. While /RST is low, no instructions can be accepted .

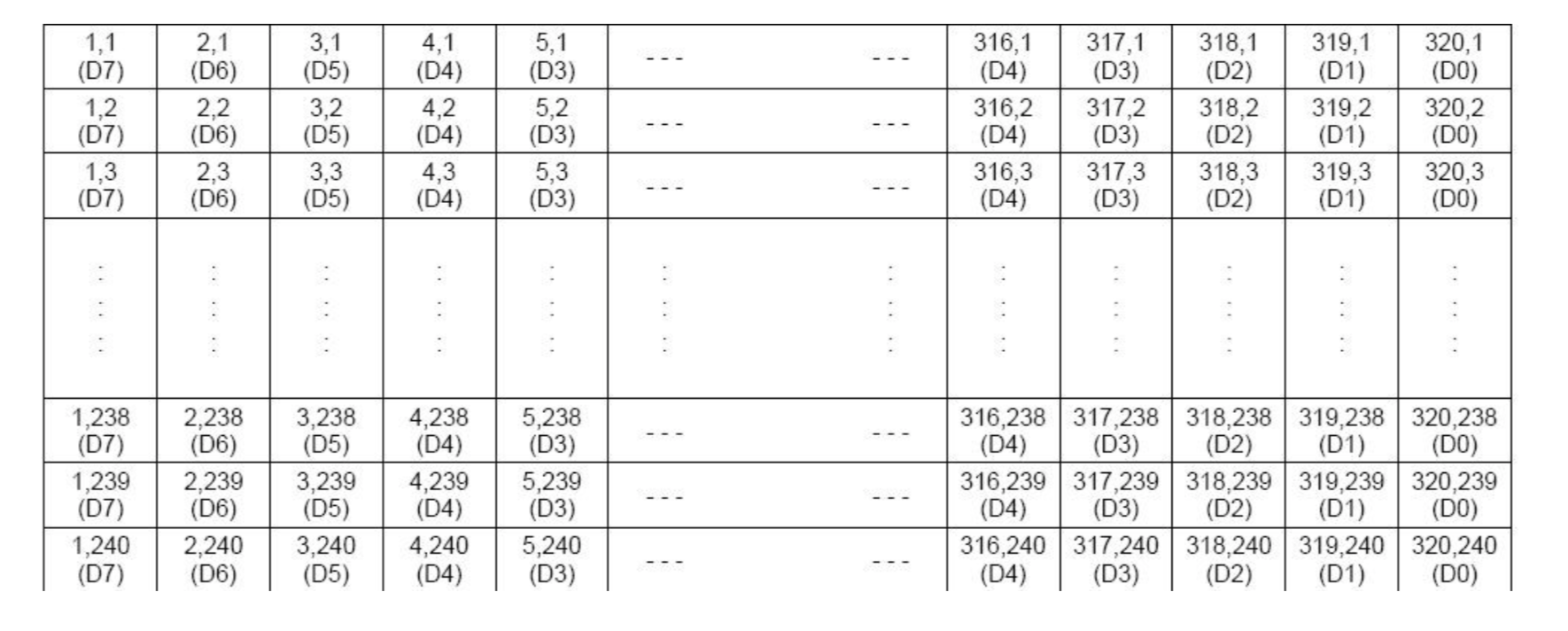

9.3. DisplayMemoryMap

Note:

一 Based on the top view of the LCD module, the 1,1(x,y) pixel is the upper-left pixel; the

320,240(x,y) pixel is the lower-right pixel.

一 For the details of memory mapping, please refer to RA8835 datasheet.

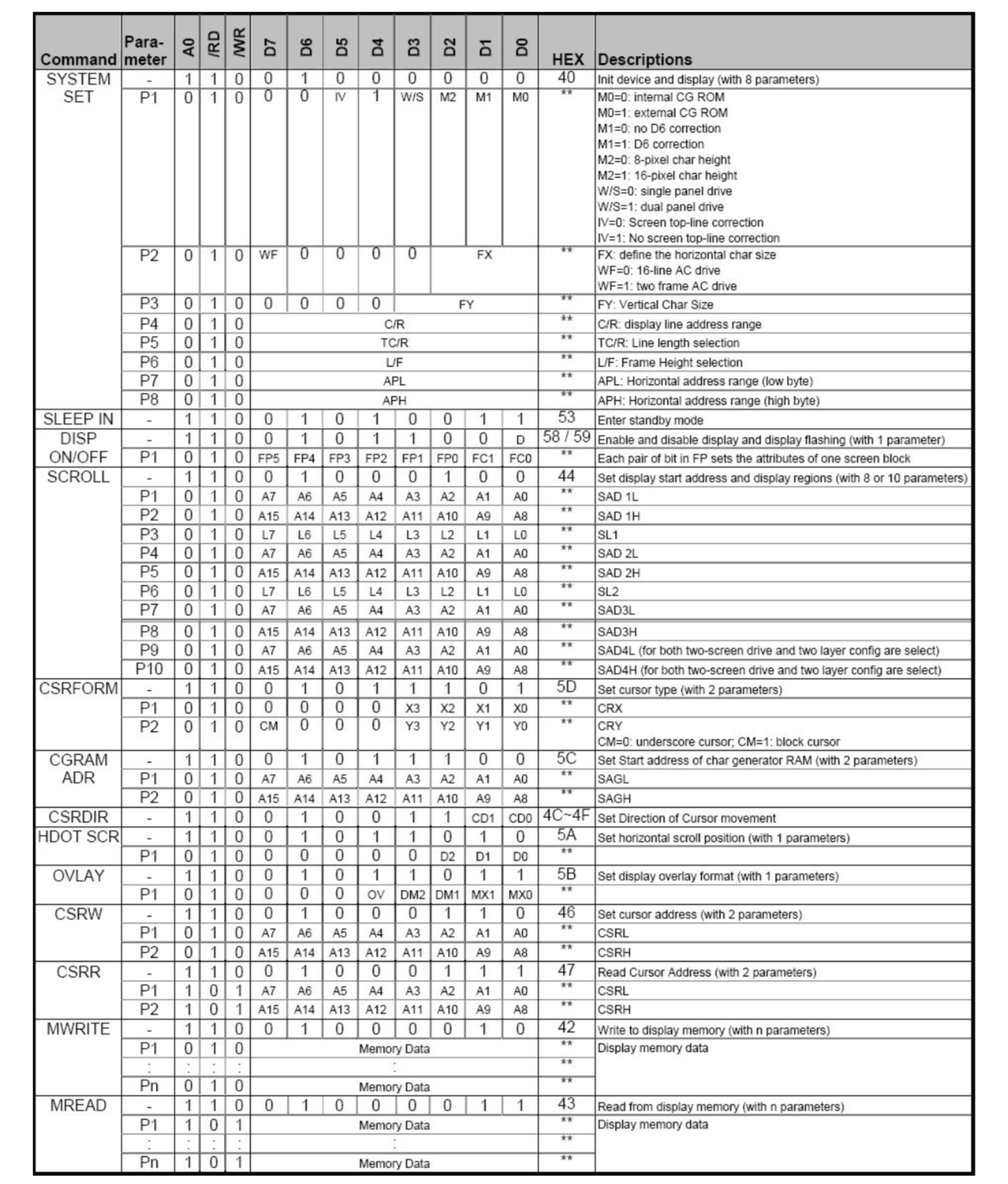

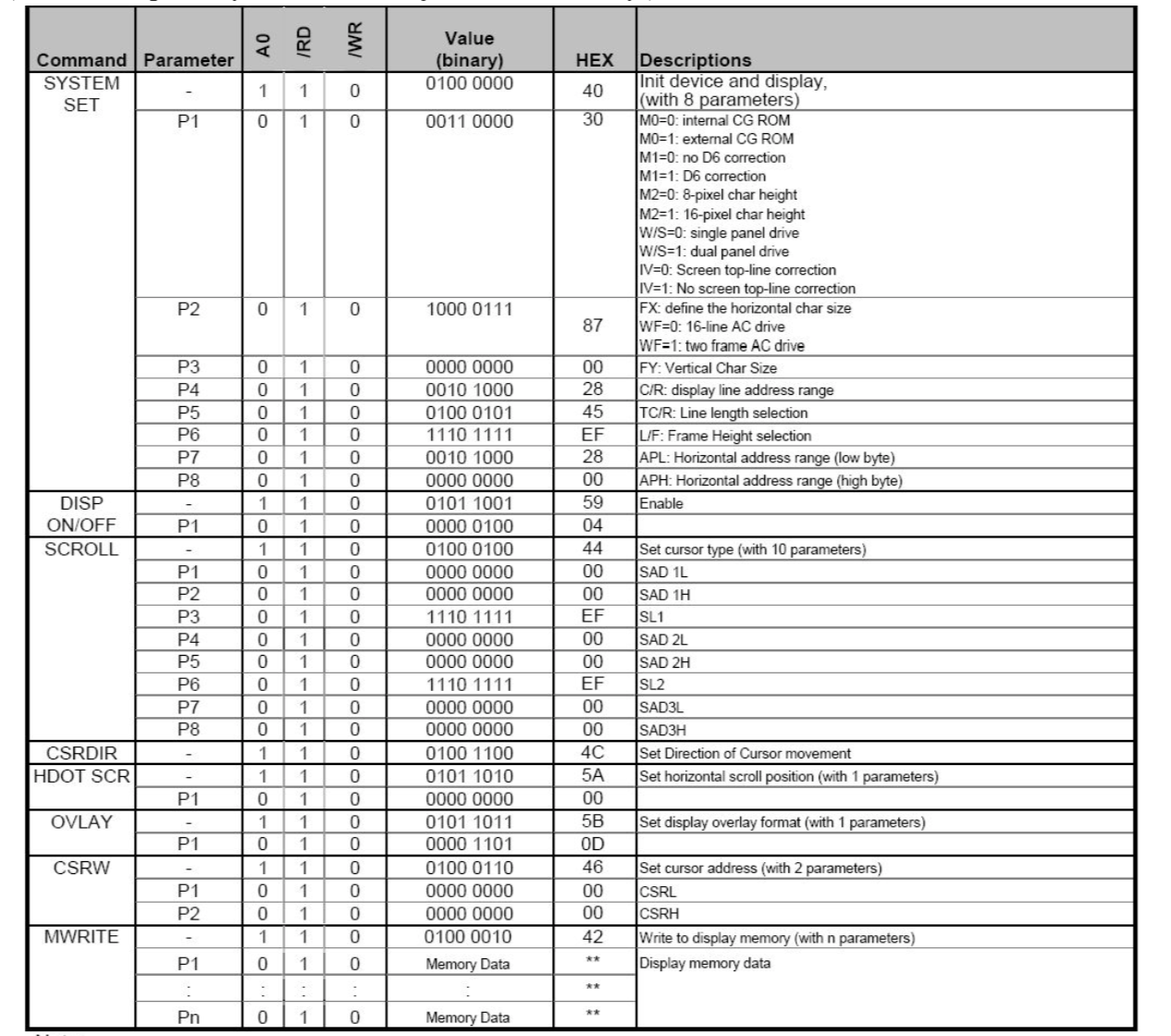

9.4. DisplayControlInstructions

Note: For the details please refer to RA8835 datasheet.

9.5. InitializationSettingExample

The following setting should be issue to LCD module after hardware reset. (It is s example only; it could be adjusted if necessary.)

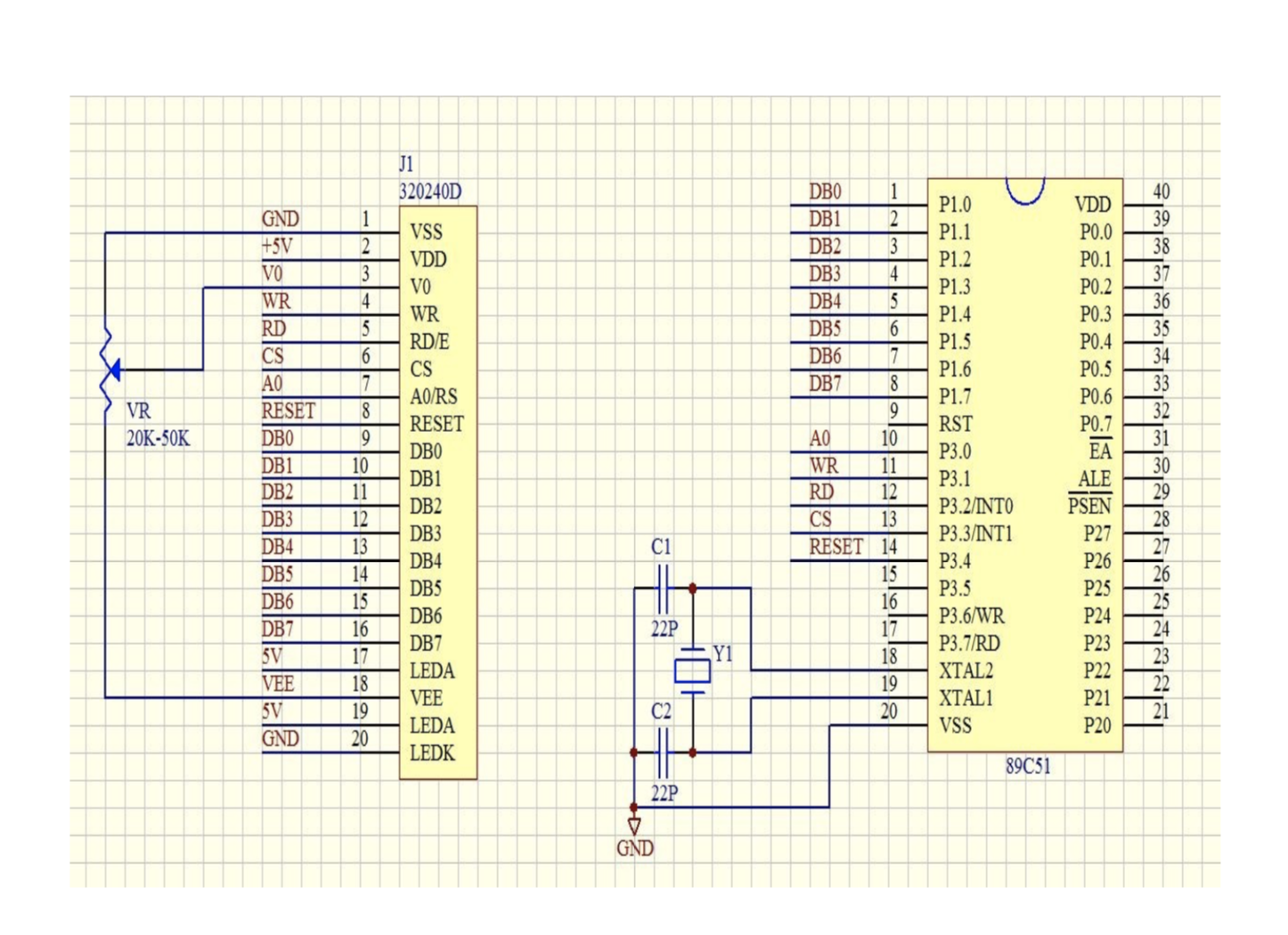

9.6. Application Circuits

10.DESIGN AND HANDING PRECAUTION

10.1. The LCD panel is made by glass. Any mechanical shock (eg. Dropping form high place) will damage the LCD module. Do not add excessive force on the surface of the display, which may cause the Display color change abnormally.

10.2. The polarizer on the LCD is easily get scratched. If possible, do not remove the LCD protective film until the last step of installation.

10.3. Never attempt to disassemble or rework the LCD module.

10.4. Only Clean the LCD with Isopropyl Alcohol or Ethyl Alcohol. Other solvents (eg.

water) may damage the LCD.

10.5. When mounting the LCD module, make sure that it is free form twisting, warping and

distortion.

10.6.Ensure to provide enough space(with cushion) between case and LCD panel to

prevent external force adding on it, or it may cause damage to the LCD or degrade the

display result

10.7. Only hold the LCD module by its side. Never hold LCD module by add force on the

heat seal or TAB.

10.8. Never add force to component of the LCD module. It may cause invisible damage or

degrade of the reliability.

10.9. LCD module could be easily damaged by static electricity. Be careful to maintain an

optimum anti-static work environment to protect the LCD module.

10.10. When peeling of the protective film form LCD, static charge may cause abnormal

display pattern. It is normal and will resume to normal in a short while.

10.11. Take care and prevent get hurt by the LCD panel edge.

10.12. Never operate the LCD module exceed the absolute maximum ratings.

10.13. Keep the signal line as short as possible to prevent noisy signal applying to LCD

module.

10.14. Never apply signal to the LCD module without power supply.

10.15. IC chip (eg. TAB or COG) is sensitive to the light. Strong lighting environment

could possibly cause malfunction. Light sealing structure casing is recommend.

10.16. LCD module reliability may be reduced by temperature shock.

10.17. When storing the LCD module, avoid exposure to the direct sunlight, high

humidity, high temperature or low temperature. They may damage or degrade the LCD module

想了解更多?現(xiàn)在就開始免費(fèi)體驗(yàn)